The mixing machines are perhaps the heaviest, dirtiest and most energy gobbling

entities in the rubber industry.

There are three types of mixing machines.

1. Rolling mills or external mixers.

2. Continuous mixers.

3. Banbury – type or internal mixers.

Except for the second type, the other two types can either be continuous or discontinuous

type.

1. Rolling mill mixers.

The rolling mill is furnished with two rolls. The rolls have internal water-cooling. Both

rolls have slightly different peripheral speeds giving a more efficient mixing.

The ratio of the peripheral speeds is usually 1:1.2. Typical roll dimensions are l = 1.5 m,

Φ = 0.5 m. The power rating is around 200 kW with a roll speed of 20 rpm. Typical

mixing cycle takes 30 min. and batch sizes are 60 – 70 kg.

At mixing, the mix is following one of the rolls and the additives are added in between

the two rolls. During mixing the roll gap is slightly opened. After mixing, the rubber strip

is cut in slices and fed in between the rolls, a number of times. This is to ensure thorough

mixing.

An important difference between rolling mills and batch mixers is that the former gives a

“good” (quality) mix while the latter gives a “fast” (productivity) mix. Furthermore,

technological advancement opportunities in the rolling mill mixing procedure are nil

compared to the internal batch mixers. Automatization is also a hurdle in rolling mill

mixers.

2. Continuous mixers.

The mixing action in a continuous mixer is similar to that in a Banbury – type mixer. The

raw materials are fed into the mixer from hoppers. The rotors or “mixing screws” in

continuous mixers can be divided into three parts – screw conveyor, mixer and pumper.

The conveyer part of the rotor propels the ingredients to the mixing part of the rotor. The

overall forward movement of the material is actually obtained by the particular geometry

of the rotors and the constant change in material viscosity as its temperature increases

along the rotor (maximum where the mixing takes place).

Thursday, July 15, 2010

WHY MIXING IS IMPORTANT

In all Rubber products, Rubber compound is a

critical component, which plays a vital role in the

performance and failure of the Product.

The composition of major Rubber Products is as

follows:

PRODUCT COMPOUND %

TYRE 80-85

TUBE 98

MOULDED GOODS 100

CONVEYOR BELTS 45-55

Compounding :

Involves deciding what ingredients and in what proportions, should be

mixed, with the goal of providing in the mixed and cured compound, the

properties required for the end application.

Mixing :

Involves deciding what equipment to use, and the speeds, pressures,

temperatures, time and procedures required to blend the chosen

ingredients into an adequately mixed compound. The aim of the mixing

process is to produce a product that has the ingredients dispersed and

distributed sufficiently thoroughly to permit it to shape readily, cure

efficiently and give the required properties for the application, all with the

minimum expenditure of machine, time and energy.

DEFINITION OF MIXING

MIXING is defined as the way different types of Raw Materials are

combined together to get a Mass that is substantially different from the

characteristics of individual components and is Homogeneous as far as

its physical and chemical properties are concerned and the same is

achieved through dispersive and distributive operation.

The principle task of compounding is concerned with securing an

acceptable balance between the demands arising between the three

considerations mainly;

1. Properties

2. Price

3. Processing

Four basiic steps are involved in the mixing operaations are

1. Incorporation : is the first stage of mixing during which the previously

separate ingredients form a coherent mass.

2. Dispersion : is the process during which the carbon black agglomerates

are reduced to their ultimate size

3. Distribution : is simple homogenization, during which the various

ingredients are randomly distributed throughout the mass of the mix.

4. Plasticization : during this operation the mix reaches its final viscosity as

plasticizers effectively lubricate the mix.

critical component, which plays a vital role in the

performance and failure of the Product.

The composition of major Rubber Products is as

follows:

PRODUCT COMPOUND %

TYRE 80-85

TUBE 98

MOULDED GOODS 100

CONVEYOR BELTS 45-55

Compounding :

Involves deciding what ingredients and in what proportions, should be

mixed, with the goal of providing in the mixed and cured compound, the

properties required for the end application.

Mixing :

Involves deciding what equipment to use, and the speeds, pressures,

temperatures, time and procedures required to blend the chosen

ingredients into an adequately mixed compound. The aim of the mixing

process is to produce a product that has the ingredients dispersed and

distributed sufficiently thoroughly to permit it to shape readily, cure

efficiently and give the required properties for the application, all with the

minimum expenditure of machine, time and energy.

DEFINITION OF MIXING

MIXING is defined as the way different types of Raw Materials are

combined together to get a Mass that is substantially different from the

characteristics of individual components and is Homogeneous as far as

its physical and chemical properties are concerned and the same is

achieved through dispersive and distributive operation.

The principle task of compounding is concerned with securing an

acceptable balance between the demands arising between the three

considerations mainly;

1. Properties

2. Price

3. Processing

Four basiic steps are involved in the mixing operaations are

1. Incorporation : is the first stage of mixing during which the previously

separate ingredients form a coherent mass.

2. Dispersion : is the process during which the carbon black agglomerates

are reduced to their ultimate size

3. Distribution : is simple homogenization, during which the various

ingredients are randomly distributed throughout the mass of the mix.

4. Plasticization : during this operation the mix reaches its final viscosity as

plasticizers effectively lubricate the mix.

MIXING

The mixing process is the beginning of any rubber plant, whether it makes tyres

or rubber articles.

Why mix at all?

1. The basic purpose of mixing is to mechanically breakdown the rubber

in an attempt to obtain a uniformly homogeneous mass, which is

subsequently formed into slabs or sheets of rubber.

2. In other words the mixing process mixes or blends the rubber with the

various constituents uniformly.

3. The mixing plasticizes the base material, i.e raw rubber.

What all go in for mixing?

Rubber (Natural rubber or Synthetic rubber), Fillers, Vulcanizing agents,

Peptizers, Accelerators, Antioxidants, Plasticizers, Process oil, Pigments, Antiozonant,

Other chemicals (Elastomers, Cobalt, Magnesium oxide, Calcium carbonate, Zinc oxide)

(Refer the section on raw materials for more information)

What are the different types of mixing?

In principle, there are two types of mixing (though there are classifications based

on other parameters also).

1. Continuous mixing.

2. Discontinuous mixing or batch mixing.

Either of the above mentioned processes usually comprise of two stages namely, the

distributive and the dispersive stages.

• The distributive mixing stage yields the master batch after primary mixing and

plasticizing. To get a good mix with the additives, the rubber has to be plastic.

The raw rubber is not plastic and is hard. The first stage mainly deals with the

mastication of rubber i.e. making the elastic rubber plastic. Thus the name

distributive as it churns and tears and distributes the elastic rubber to get a

sticky plastic yielding compound.

• The dispersive stage serves for the final dispersion of the vulcanizing agents

The mixers used in both stages of the continuous mixing process are of the

continuous type. Typically, a continuous mixer consists of screws rotating in cylindrical

chambers, in which the material to be mixed enters and leaves continuously.

On the other hand, in batch mixing the first stage is served by the batch mixer

followed by the second mixing stage in a rolling mill or a continuous mixer. Sometimes,

rolling mills are used in both stages. If such is the case, they operate discontinuously.

or rubber articles.

Why mix at all?

1. The basic purpose of mixing is to mechanically breakdown the rubber

in an attempt to obtain a uniformly homogeneous mass, which is

subsequently formed into slabs or sheets of rubber.

2. In other words the mixing process mixes or blends the rubber with the

various constituents uniformly.

3. The mixing plasticizes the base material, i.e raw rubber.

What all go in for mixing?

Rubber (Natural rubber or Synthetic rubber), Fillers, Vulcanizing agents,

Peptizers, Accelerators, Antioxidants, Plasticizers, Process oil, Pigments, Antiozonant,

Other chemicals (Elastomers, Cobalt, Magnesium oxide, Calcium carbonate, Zinc oxide)

(Refer the section on raw materials for more information)

What are the different types of mixing?

In principle, there are two types of mixing (though there are classifications based

on other parameters also).

1. Continuous mixing.

2. Discontinuous mixing or batch mixing.

Either of the above mentioned processes usually comprise of two stages namely, the

distributive and the dispersive stages.

• The distributive mixing stage yields the master batch after primary mixing and

plasticizing. To get a good mix with the additives, the rubber has to be plastic.

The raw rubber is not plastic and is hard. The first stage mainly deals with the

mastication of rubber i.e. making the elastic rubber plastic. Thus the name

distributive as it churns and tears and distributes the elastic rubber to get a

sticky plastic yielding compound.

• The dispersive stage serves for the final dispersion of the vulcanizing agents

The mixers used in both stages of the continuous mixing process are of the

continuous type. Typically, a continuous mixer consists of screws rotating in cylindrical

chambers, in which the material to be mixed enters and leaves continuously.

On the other hand, in batch mixing the first stage is served by the batch mixer

followed by the second mixing stage in a rolling mill or a continuous mixer. Sometimes,

rolling mills are used in both stages. If such is the case, they operate discontinuously.

COMPOUND FORMULATION

Prior to the “Banbury” or compound mixing comes the compound formulation.

The two major compounds in the rubber compound are the rubber and the filler, each

having its own functionality. The mixing of these raw materials and their proportions and

nature is determined by the purpose for which the compound is made. It may be for

superior rolling resistance or better grip on both dry and wet roads. The properties of the

mix can be changed by selecting one or more types of rubber and filler and their grades

and proportions in which they have to be present.

The two major compounds in the rubber compound are the rubber and the filler, each

having its own functionality. The mixing of these raw materials and their proportions and

nature is determined by the purpose for which the compound is made. It may be for

superior rolling resistance or better grip on both dry and wet roads. The properties of the

mix can be changed by selecting one or more types of rubber and filler and their grades

and proportions in which they have to be present.

Dipping solution

Dipping solutions are resorcinol- formaldehyde condensation products used as

adhesion promoters. Reinforcing materials such as rayon, nylon, polyester, aramid, steel

and fiberglass cords are all bonded to rubber with resorcinol or resorcinol based bonding

agent. Nowadays, RFL (resorcinol Formaldehyde Latex) is used for dipping organic

fibers such as polyester, nylon, rayon, or aramid

Some thermoplastic resorcinol based resins can also be used for dipping but they

need additives (like hexamethoxymethylmelamine or hexamethylenetetramine) to

complete the reaction and become thermoset.

adhesion promoters. Reinforcing materials such as rayon, nylon, polyester, aramid, steel

and fiberglass cords are all bonded to rubber with resorcinol or resorcinol based bonding

agent. Nowadays, RFL (resorcinol Formaldehyde Latex) is used for dipping organic

fibers such as polyester, nylon, rayon, or aramid

Some thermoplastic resorcinol based resins can also be used for dipping but they

need additives (like hexamethoxymethylmelamine or hexamethylenetetramine) to

complete the reaction and become thermoset.

Metal cord

Beads are wire hoops on each side of the tyre to anchor it firmly to the rim of the

wheel. The core material is high tensile strength, high fatigue strength steel wire often

coated with substances like copper or bronze to increase its adherability to rubber. Steel

wire quality is based on tensile strength, elongation and stiffness. It is manufactured from

steel rood with high carbon content.

One difference between the multi – ply tyre and the belted tyre is the property of

the steel cord that is used. In the former, the fatigue life of the steel cords will be the

dominating aspect while in the latter; the stiffness will be of primary concern.

tyre breaker belts as well as the casing ply in many truck tyres. The brass coating is done

because rubber will not adhere to bare steel. Also, more the rubber penetrates, more is the

rust resistance. And though the steel cords come in various configurations such as in

cross sections of pairs and triplets, all are brass – coated strands twisted together into

cords.

The storage of these brass coated steel cords should be in a temperature and

humidity controlled environment (the creel room). Even the distance between the creel

room and the calendar must not be too large. Otherwise, corrosion due to moisture may

cause the steel belts to lose adhesion with rubber.

wheel. The core material is high tensile strength, high fatigue strength steel wire often

coated with substances like copper or bronze to increase its adherability to rubber. Steel

wire quality is based on tensile strength, elongation and stiffness. It is manufactured from

steel rood with high carbon content.

One difference between the multi – ply tyre and the belted tyre is the property of

the steel cord that is used. In the former, the fatigue life of the steel cords will be the

dominating aspect while in the latter; the stiffness will be of primary concern.

High tensile brass coated steel cords (multi strand) are used in the construction of

tyre breaker belts as well as the casing ply in many truck tyres. The brass coating is done

because rubber will not adhere to bare steel. Also, more the rubber penetrates, more is the

rust resistance. And though the steel cords come in various configurations such as in

cross sections of pairs and triplets, all are brass – coated strands twisted together into

cords.

The storage of these brass coated steel cords should be in a temperature and

humidity controlled environment (the creel room). Even the distance between the creel

room and the calendar must not be too large. Otherwise, corrosion due to moisture may

cause the steel belts to lose adhesion with rubber.

Textile fabric

The fabric gives shape, strength and reinforcement to the tyre cover. In earlier

days square woven fabrics were used but now weft less fabrics are being used which have

fiber threads in parallel with just enough cross threads to hold the parallel strands in place

before it is impregnated with rubber. Too much cross threads will cause friction and wear

in ride conditions. Each individual thread in the parallel strand is called a cord. Fabric

cord quality is based on its strength, stretch, elasticity and shrinkage

. In earlier days cotton was used but during 1939-45 war when cotton became

scarce, synthetic fibers like rayon were utilized. Synthetic fibers had better resistance to

more heat generated in synthetic tyres. For heavy-duty tyres, fine twisted steel cords are

used. Other synthetic fibers include nylon, aramid, fiberglass and polyester. Normal

fibers in use now are nylon and plyester

reduce centerline buckling under low inflation.

Synthetic fibers come in the form of yarn, raw fabric and dipped fabric. They

usually come in the form of huge rolls and are specialized and critical to the rubber

process.

days square woven fabrics were used but now weft less fabrics are being used which have

fiber threads in parallel with just enough cross threads to hold the parallel strands in place

before it is impregnated with rubber. Too much cross threads will cause friction and wear

in ride conditions. Each individual thread in the parallel strand is called a cord. Fabric

cord quality is based on its strength, stretch, elasticity and shrinkage

. In earlier days cotton was used but during 1939-45 war when cotton became

scarce, synthetic fibers like rayon were utilized. Synthetic fibers had better resistance to

more heat generated in synthetic tyres. For heavy-duty tyres, fine twisted steel cords are

used. Other synthetic fibers include nylon, aramid, fiberglass and polyester. Normal

fibers in use now are nylon and plyester

Aramid fibers are used in the tread area to provide high-speed performance and

reduce centerline buckling under low inflation.

Synthetic fibers come in the form of yarn, raw fabric and dipped fabric. They

usually come in the form of huge rolls and are specialized and critical to the rubber

process.

Antioxidants

Antioxidants resist the deterioration caused by rubber’s tendency to absorb

oxygen from the atmosphere. There are heat resistant antioxidants, antioxidants with

antiozonant properties and antioxidants with antiflex properties

oxygen from the atmosphere. There are heat resistant antioxidants, antioxidants with

antiozonant properties and antioxidants with antiflex properties

Accelerators

Accelerators reduce the time and temperature required for the vulcanization. The

variants are classified based on rate at which they accelerate the vulcanization or as

delayed action accelerators. Some accelerators are simply sulphur donors.

variants are classified based on rate at which they accelerate the vulcanization or as

delayed action accelerators. Some accelerators are simply sulphur donors.

Peptizers

A peptizing agent reduces the milling time but does not affect the cure

characteristics of the rubber. Hence addition of a peptizer reduces the compounding time

needed in a mill or mixer. E.g. Dibenzamido Diphenyl Disulphide.

characteristics of the rubber. Hence addition of a peptizer reduces the compounding time

needed in a mill or mixer. E.g. Dibenzamido Diphenyl Disulphide.

Tuesday, July 13, 2010

RAW MATERIALS FOR TYRES

Fillers and reinforcing agents

Carbon black gives resistance to wear. Without which the life of the tyre will be

very much reduced. In the tread half of the weight of raw rubber is carbon black. It is

prepared by burning crude oil in special furnaces. There are different grades of carbon

black which are used. One type is used in tyre casings where resistance to heat generated

in normal running is the main requirement. And specifically, the grades are different for

the sidewall, tread and apex.

Other fillers include white carbon or Silicon dioxide (Silica) and Kaolin clay.

Especially silica is used in some tread compounds so as to reduce the tyre’s forward

rolling resistance which reduces the fuel consumption while maintaining properties like

wet grip and better winter performance. A more detailed description of silica technology

is given under the section concerning tyre tread patterns.

Carbon black gives resistance to wear. Without which the life of the tyre will be

very much reduced. In the tread half of the weight of raw rubber is carbon black. It is

prepared by burning crude oil in special furnaces. There are different grades of carbon

black which are used. One type is used in tyre casings where resistance to heat generated

in normal running is the main requirement. And specifically, the grades are different for

the sidewall, tread and apex.

Other fillers include white carbon or Silicon dioxide (Silica) and Kaolin clay.

Especially silica is used in some tread compounds so as to reduce the tyre’s forward

rolling resistance which reduces the fuel consumption while maintaining properties like

wet grip and better winter performance. A more detailed description of silica technology

is given under the section concerning tyre tread patterns.

RAW MATERIALS FOR TYRES

Rubber

In its natural form (without any additives), natural as well as synthetic

rubber is useless as its consistency varies with temperature and its elasticity is lost in

prolonged tension. Thus the need for additives. Natural rubber usually comes in the form

of “ribbed smoked rubber sheets” in weights of 30-110kg

Synthetic rubber is used as a substitute for natural rubber. Historically, one

of the first synthetic variants was “Methyl-rubber” produced in Germany during the

1914-18 war. The raw materials used were coal and limestone (Germany, Russia). Others

experimented with other raw materials such as alcohol (U.S.A, Italy, Russia), petroleum

(U.S.A, Russia) and natural gas (Germany). A major breakthrough in synthetic rubber

evolution was the development of Buna S 3 during the 1939-45 war by Germany. On the

other hand in U.S.A, the variants were GR-S, Neoprene, Butyl rubber and GR-N (Buna

N). These synthetic variants virtually made the production of tyres possible without the

use of any natural rubber.

Natural rubber, styrene butadiene rubber(SBR) and polybutadiene rubber(BR) are

primarily used for tread and sidewalls. On the other hand butyl and halobutyl rubbers are

used in inner liners.

Synthetic rubber has some advantages over natural rubber in terms of physical

properties such as wear and abrasion resistance but there is no perfect synthetic

alternative to natural rubber. Nowadays synthetic rubber comes as oil-inclusive (paraffin

or aromatic oil), staining/non-staining, acrylonitrile based, styrene based and so on.

In its natural form (without any additives), natural as well as synthetic

rubber is useless as its consistency varies with temperature and its elasticity is lost in

prolonged tension. Thus the need for additives. Natural rubber usually comes in the form

of “ribbed smoked rubber sheets” in weights of 30-110kg

Synthetic rubber is used as a substitute for natural rubber. Historically, one

of the first synthetic variants was “Methyl-rubber” produced in Germany during the

1914-18 war. The raw materials used were coal and limestone (Germany, Russia). Others

experimented with other raw materials such as alcohol (U.S.A, Italy, Russia), petroleum

(U.S.A, Russia) and natural gas (Germany). A major breakthrough in synthetic rubber

evolution was the development of Buna S 3 during the 1939-45 war by Germany. On the

other hand in U.S.A, the variants were GR-S, Neoprene, Butyl rubber and GR-N (Buna

N). These synthetic variants virtually made the production of tyres possible without the

use of any natural rubber.

Natural rubber, styrene butadiene rubber(SBR) and polybutadiene rubber(BR) are

primarily used for tread and sidewalls. On the other hand butyl and halobutyl rubbers are

used in inner liners.

Synthetic rubber has some advantages over natural rubber in terms of physical

properties such as wear and abrasion resistance but there is no perfect synthetic

alternative to natural rubber. Nowadays synthetic rubber comes as oil-inclusive (paraffin

or aromatic oil), staining/non-staining, acrylonitrile based, styrene based and so on.

TREAD PATTERNS

The tread pattern decides many important properties of the tyre. Some being

rolling resistance, directional stability, steering control, braking, acceleration, water

dispersion and so on. Some tread patterns are discussed below. Typically, more the tread

depth less the braking distance and more the fuel consumption as rolling resistance

increases.

Another important feature is the rolling resistance which is measured in terms of

the energy the tyre consumes when it revolves and deflects. More rolling resistance

meant more energy consumption and less rolling resistance meant reduction in wet grip

performance. Replacement of some quantity of carbon black in the tread compound with

silica has enabled reduction of rolling resistance, better winter performance and better

wet skid properties all at the same time.

As stated grip and rolling resistance are contradicting requirements to be

satisfied. Technically speaking, grip deals with the distortion in the tyre at high

frequencies – or in other words on the degree of unevenness on the road and the number

of small stones it hits on the road. Good grip is given by rubber compounds which absorb

high levels of energy (high hysteresis compounds)

On the other hand, rolling resistance is affected by low frequency distortion – or

in other words the deflection of the tyre as it revolves. Low rolling resistance needs

compounds which absorb less energy (low hysteresis compounds)

The genius behind adding silica is that by doing so tyre engineers have created a

compound which has high hysteresis at high frequencies and low hysteresis at low

frequencies.

Rib treads – Tread patterns are in the form of parallel circumferential groove

(Here, circumference denotes that of the tyre).

The tyre has good lateral resistance so it has good directional stability and

steering control. Rib pattern is good for sustained high speeds due to less resistance to

forward motion (or less rolling resistance) and so less heat generation. But the tread

pattern has poor acceleration and grip on wet roads.

Used in paved road surfaces and bus or truck steer axles.

Lug treads – Tread patterns are in the form of grooves perpendicular to the

circumference of the tyre.

The lug tread pattern has excellent braking power and traction. Has very high

rolling resistance and is the main reason why it is not suitable for high speeds.

Used on dirt roads, rear wheels of buses, industrial vehicles and dump trucks.

Rib-lug treads – This is a combination of rib and lug treads.

The circumferential rib treads in the centre give good directional control while the

shoulder lug tread gives good braking and driving power.

Used for both paved and dirt roads and as both rear and front wheels of trucks and

buses.

Block treads – The pattern consists of independent blocks divided by

circumferential and lateral grooves.

Block patterns give good steering control on snow covered and wet roads and

water dispersal properties. Because of smaller tread blocks tyre wear is more.

Used for winter tyres.

Asymmetric treads – These tread patterns try to optimize the opposing properties

of dry grip and water dispersal. The tread pattern on the inner side has more grooves

giving better grip on wet roads. The higher plane surface area on the outer side are better

suited for high speed cornering due to greater contact area which also helps reduce tread

wear. Asymmetric tyres should always be placed the right way around.

Used in high performance and motor sport tyres.

Directional treads – This pattern is characterized by lateral grooves on both sides

of the tyre pointing in the same direction. They are designed to rotate in one direction

only so that many properties get optimized. They give good traction and braking

properties and have good stability on wet roads (which means good water dispersal).

Must be mounted in the direction of tread pattern.

Used in high-speed passenger car tyres.

rolling resistance, directional stability, steering control, braking, acceleration, water

dispersion and so on. Some tread patterns are discussed below. Typically, more the tread

depth less the braking distance and more the fuel consumption as rolling resistance

increases.

Another important feature is the rolling resistance which is measured in terms of

the energy the tyre consumes when it revolves and deflects. More rolling resistance

meant more energy consumption and less rolling resistance meant reduction in wet grip

performance. Replacement of some quantity of carbon black in the tread compound with

silica has enabled reduction of rolling resistance, better winter performance and better

wet skid properties all at the same time.

As stated grip and rolling resistance are contradicting requirements to be

satisfied. Technically speaking, grip deals with the distortion in the tyre at high

frequencies – or in other words on the degree of unevenness on the road and the number

of small stones it hits on the road. Good grip is given by rubber compounds which absorb

high levels of energy (high hysteresis compounds)

On the other hand, rolling resistance is affected by low frequency distortion – or

in other words the deflection of the tyre as it revolves. Low rolling resistance needs

compounds which absorb less energy (low hysteresis compounds)

The genius behind adding silica is that by doing so tyre engineers have created a

compound which has high hysteresis at high frequencies and low hysteresis at low

frequencies.

Rib treads – Tread patterns are in the form of parallel circumferential groove

(Here, circumference denotes that of the tyre).

The tyre has good lateral resistance so it has good directional stability and

steering control. Rib pattern is good for sustained high speeds due to less resistance to

forward motion (or less rolling resistance) and so less heat generation. But the tread

pattern has poor acceleration and grip on wet roads.

Used in paved road surfaces and bus or truck steer axles.

Lug treads – Tread patterns are in the form of grooves perpendicular to the

circumference of the tyre.

The lug tread pattern has excellent braking power and traction. Has very high

rolling resistance and is the main reason why it is not suitable for high speeds.

Used on dirt roads, rear wheels of buses, industrial vehicles and dump trucks.

Rib-lug treads – This is a combination of rib and lug treads.

The circumferential rib treads in the centre give good directional control while the

shoulder lug tread gives good braking and driving power.

Used for both paved and dirt roads and as both rear and front wheels of trucks and

buses.

circumferential and lateral grooves.

Block patterns give good steering control on snow covered and wet roads and

water dispersal properties. Because of smaller tread blocks tyre wear is more.

Used for winter tyres.

Asymmetric treads – These tread patterns try to optimize the opposing properties

of dry grip and water dispersal. The tread pattern on the inner side has more grooves

giving better grip on wet roads. The higher plane surface area on the outer side are better

suited for high speed cornering due to greater contact area which also helps reduce tread

wear. Asymmetric tyres should always be placed the right way around.

Used in high performance and motor sport tyres.

Directional treads – This pattern is characterized by lateral grooves on both sides

of the tyre pointing in the same direction. They are designed to rotate in one direction

only so that many properties get optimized. They give good traction and braking

properties and have good stability on wet roads (which means good water dispersal).

Must be mounted in the direction of tread pattern.

Used in high-speed passenger car tyres.

TYRE CALSSES

Pneumatic tyres vary widely in size and weight with cross sections ranging from 1

inch to 21 inches. The most important functions of a tyre used in the automobile industry

are to absorb shock, and so reduce wear on vehicle and road and to grip the road for

braking, steering and transmission of power.

The main classes of tyre include-Car, Giant, Agricultural and Industrial, Aircraft,

Motor cycle and Cycle.

Also the tyres are classified as summer, winter or all season tyres.

Summer tyres- The main characteristic of a summer tyre is excellent driving and braking

performance on both dry and wet roads, in temperatures above freezing in all seasons. A

simple block shaped tread pattern ensures that it maintains maximum grip on a road

surface at all times.

Winter tyres-The winter tyre is suitable for ice and snow covered roads. The tread is

heavily siped, fine block design with grooves that are deep and wide providing excellent

traction and braking performance on such roads. The tread rubber used here is having

better friction characteristics and retains suppleness even at low temperatures.

longer block edge for winter usage. More sipes occur in all season tyres than summer

tyres to improve traction and braking performance by maximizing the effect of edge.

inch to 21 inches. The most important functions of a tyre used in the automobile industry

are to absorb shock, and so reduce wear on vehicle and road and to grip the road for

braking, steering and transmission of power.

The main classes of tyre include-Car, Giant, Agricultural and Industrial, Aircraft,

Motor cycle and Cycle.

Also the tyres are classified as summer, winter or all season tyres.

Summer tyres- The main characteristic of a summer tyre is excellent driving and braking

performance on both dry and wet roads, in temperatures above freezing in all seasons. A

simple block shaped tread pattern ensures that it maintains maximum grip on a road

surface at all times.

Winter tyres-The winter tyre is suitable for ice and snow covered roads. The tread is

heavily siped, fine block design with grooves that are deep and wide providing excellent

traction and braking performance on such roads. The tread rubber used here is having

better friction characteristics and retains suppleness even at low temperatures.

All season tyres-These tyres are more complicated than summer tyres because of the

longer block edge for winter usage. More sipes occur in all season tyres than summer

tyres to improve traction and braking performance by maximizing the effect of edge.

RADIAL TYRES

Most steel belted radial tyres are made of an inner liner, two polyester reinforced

body plies, two steel beads, two bead reinforcing strips, two chafers or anti – chafing

strips, two steel belts, two sidewalls and the tread. Some tyres also have one or two layers

of nylon or polyester reinforced sheets just below the tread and above the steel belt.

These are called “safety belts” or “cap plies”.

Radial-ply technology versus Bias –ply technology

Technically, these two variants differ in the way the ply cords (which means the

layers of fabric that makeup the body of the tyre) are layered in the body of the tyre. In

bias tyres the ply cords are at an angle to the direction of rotation or diagonally across the

tyre from bead to bead. These ply layers alternate in direction to reinforce each other.

On the other hand in radial tyres the ply cords are perpendicular to the direction of

rotation or run radially across the tyre from bead to bead. This means that they run

parallel to each other from bead to bead (with each individual cord running up the

sidewall, across the tread and down the other sidewall). This results in a cooler running

tyre that has more sidewall flexibility and better directional stability.

One common characteristic in belted bias-ply tyres and radial tyres is the need for

stabilizer belts made of sheets reinforced with fiberglass, steel or kevlar.

One difference between the multi – ply tyre and the belted tyre is the property of

the steel cord that is used. In the former, the fatigue life of the steel cords will be the

dominating aspect while in the latter; the stiffness will be of primary concern.

Performance wise, radial tyres surpass bias tyres when it comes to smooth rides

on bumpy roads and tyre grip on wet road conditions. Other plus points for radial tyres

are better braking and cornering power, better gas mileage and a higher life expectancy.

The strongest possible bond between the rubber and the steel belt wire is critical

in the construction of steel belted radial tyres. The most common failure mode of steel

belted radial tyres is separation in components in the area where the steel belt is placed.

During tyre usage, this area is subject to heavy stresses. Combined with the fact that

rubber adhesion to metal (here steel) is very weak makes this area prone to failure in

terms of separation of tyre components. Other factors affecting adhesion are mishandling

of components during usage and storage, accumulation of moisture on the steel belts

during processing, formation of pockets of air near the steel belts, contamination and last

but not the least undercuring.

body plies, two steel beads, two bead reinforcing strips, two chafers or anti – chafing

strips, two steel belts, two sidewalls and the tread. Some tyres also have one or two layers

of nylon or polyester reinforced sheets just below the tread and above the steel belt.

These are called “safety belts” or “cap plies”.

Radial-ply technology versus Bias –ply technology

Technically, these two variants differ in the way the ply cords (which means the

layers of fabric that makeup the body of the tyre) are layered in the body of the tyre. In

bias tyres the ply cords are at an angle to the direction of rotation or diagonally across the

tyre from bead to bead. These ply layers alternate in direction to reinforce each other.

On the other hand in radial tyres the ply cords are perpendicular to the direction of

rotation or run radially across the tyre from bead to bead. This means that they run

parallel to each other from bead to bead (with each individual cord running up the

sidewall, across the tread and down the other sidewall). This results in a cooler running

tyre that has more sidewall flexibility and better directional stability.

One common characteristic in belted bias-ply tyres and radial tyres is the need for

stabilizer belts made of sheets reinforced with fiberglass, steel or kevlar.

One difference between the multi – ply tyre and the belted tyre is the property of

the steel cord that is used. In the former, the fatigue life of the steel cords will be the

dominating aspect while in the latter; the stiffness will be of primary concern.

Performance wise, radial tyres surpass bias tyres when it comes to smooth rides

on bumpy roads and tyre grip on wet road conditions. Other plus points for radial tyres

are better braking and cornering power, better gas mileage and a higher life expectancy.

The strongest possible bond between the rubber and the steel belt wire is critical

in the construction of steel belted radial tyres. The most common failure mode of steel

belted radial tyres is separation in components in the area where the steel belt is placed.

During tyre usage, this area is subject to heavy stresses. Combined with the fact that

rubber adhesion to metal (here steel) is very weak makes this area prone to failure in

terms of separation of tyre components. Other factors affecting adhesion are mishandling

of components during usage and storage, accumulation of moisture on the steel belts

during processing, formation of pockets of air near the steel belts, contamination and last

but not the least undercuring.

TYRE SPECIFICATIONS

Take for example the sidewall marking

215/50 R15 91V E4

1. “215” – Width of the tyre in mm from sidewall to sidewall.

2. “50” – Called the aspect ratio. This gives the height of the tyre sidewall as a %

of the width of the tyre. In this case it is 50% of 215 mm.

3. “R” – Denotes radial construction. (“B” indicates bias ply)

4. “15” – The diameter of tyre’s rim in inches.

5. “91” – Maximum load capacity of the tyre (see load table below)when

properly inflated. In this case it is 615 Kg.

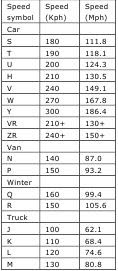

6. “V” – Indicates the maximum service speed of the tyre at full load (see speed

table below). In this case it is 240 Kmph.

7. “E4” – ECE type approval mark for sale in the European community. Other

compliant markings include “DOT” (U.S Department of Transportation),

“UTQG”(Uniform tyre Quality Grading)

Load table

The load capacity of the tyre determines what payload each tyre can carry. The table

below gives the load index and the load rating in Kg.

tyre wear is even and the life of the full set of tyres is extended. On the other hand radial

tyres should not be switched from one side to another because the cords tend to develop a

”set” due to flexing of cords during driving. Reversing the side may result in cord failure.

215/50 R15 91V E4

1. “215” – Width of the tyre in mm from sidewall to sidewall.

2. “50” – Called the aspect ratio. This gives the height of the tyre sidewall as a %

of the width of the tyre. In this case it is 50% of 215 mm.

3. “R” – Denotes radial construction. (“B” indicates bias ply)

4. “15” – The diameter of tyre’s rim in inches.

5. “91” – Maximum load capacity of the tyre (see load table below)when

properly inflated. In this case it is 615 Kg.

6. “V” – Indicates the maximum service speed of the tyre at full load (see speed

table below). In this case it is 240 Kmph.

7. “E4” – ECE type approval mark for sale in the European community. Other

compliant markings include “DOT” (U.S Department of Transportation),

“UTQG”(Uniform tyre Quality Grading)

Load table

The load capacity of the tyre determines what payload each tyre can carry. The table

below gives the load index and the load rating in Kg.

Generally it is advisable to rotate the tyre positions (i.e switch the tyres) so that

tyre wear is even and the life of the full set of tyres is extended. On the other hand radial

tyres should not be switched from one side to another because the cords tend to develop a

”set” due to flexing of cords during driving. Reversing the side may result in cord failure.

TYRE PARTS

Sidewalls

Sidewalls have two conflicting uses, one is to flex up and down acting as a shock

absorber during normal movement of the tyre on the road and to still be rigid enough to

bear the forces that come into play during normal running, braking, accelerating and

steering.

Several manufacturers have developed tyres that allow a vehicle to continue

moving despite loss of pressure. This is called Run Flat technology. One of the

approaches used by Bridgestone (RFT Series), Dunlop (DSST Series), Goodyear (EMT

Series) and Pirelli (Euphori) is the Reinforced tyre Sidewall. Whatever be the approach, it

must operate in tandem with the tyre pressure warning systems.

These tyres can be put on any rim. In these tyres the sidewall is reinforced with

inserts that are made of a highly resilient compound with high stiffness and low

hysteresis allowing the tyre to support the vehicle weight. New compounds are used in

the sidewall to prevent tyre destruction due to excessive flexing.

Casing plies

The term “ply” refers to a layer of fabric cords that is used to reinforce the tyre

casing. Without this reinforcement, on inflation the tyre will not have the required shape,

strength and structure. As stated earlier in a bias-ply tyre, two or four layers of cords are

wrapped at a 30 - 38 degree angle from bead to bead. And for stability reasons the layers

must be even with alternate direction of cords. And in a radial tyre the cords run at right

angles to the bead wires.

Rubber Breaker

Also called stabilizer belts or safety belts and are usually two in number. These

are belt layers under the tread section and are made of fiberglass, steel or Kevlar. These

reduce tread “squirm” on the road surface. In radial tyres also, the belts have to be

provided to prevent the tread area from “rolling” during cornering.

Another technology is the spiral winding technology.

Apex

The apex is also called the ”bead filler”. The apex stiffens the area just above the

beads and gives it strength and resilience during tyre mounting. Another device used in

some tyres is the rim flange protector that comes at the point where the wheel rim and

tyre meet.

Inner liner

The inner liner is a very critical component. It is a substitute for the tube used in

older style tyres. It is a double layer of synthetic gum rubber (butyl or halobutyl rubber)

that serves the purpose of sealing in the air and making the tyre tubeless. The main

functions of the rubber compound formulation for the inner liner are to provide the least

amount of air permeability (the butyl/halo – butyl rubber used here just does that)

possible and to strongly adhere to the body plies.

Beads

Beads are shaped like hoops and are non - extensible. It has a high tensile and

high fatigue life steel wire (coated with brass) as it backbone. (Sometimes Kevlar is also

used). The bead fits against the wheel rim. Strands of steel are arranged sided by side in

the form of a ribbon and are coated with rubber for good adhesion. Special shapes like

pentagonal beads are used which provide extra stability under low inflation conditions

and prevents the bead from slipping off the rim bead seat.

Bead wires come in different configurations like weft less, cable beads and single

strand. Similar to steel cords used in steel belts of radial tyres, these are also transported

in hermetically sealed containers and appropriate precautions have to be taken to prevent

contamination by impurities like moisture and dust leading to corrosion and thus loss of

adherence to rubber while coating.

The main function of the bead loop is to support or anchor the body plies and to

prevent the wheel from slipping or rocking the rim.

Chafer

These narrow strips of reinforcing pliant fabrics are so called because they resist

the chafing from the wheel rim. Chafers add dimensional stability as well as gives high

adhesion to rubber.

Just like the Reinforced tyre Sidewall concept described above, Michelin uses a

concept called the PAX system. Like the former this also operates in line with the tyre

pressure monitoring systems. The rubber clip over the rim prevents the tyre from cutting

into the tyre when there is a loss of pressure. The clip element is several centimeters thick

and is of the same width as the tread.

Subscribe to:

Comments (Atom)