“mix” directly into the mill.

2. Mixer with conveyer to rolling mill. The “mix” is taken to the rolling mill on a

conveyer.

3. Mixer in combination with an extruder. The “mix” is dumped directly into an

extruder.

The important specifications of a mixer include the mixing chamber volume (in

liters), batch size (in kg.), maximum rotor speed (in rpm) and installed power/rpm

(kW/rpm)

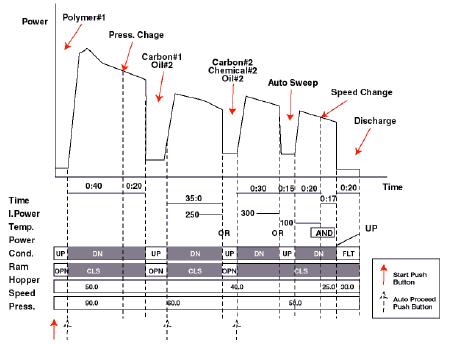

What could be the mixing sequence? (An example)

No comments:

Post a Comment